FUNCTIONAL CORE SHOOTER MACHINES

Versatility, practicality, comfort, speed, economy… these are the qualities provided by the core shooter we are going to talk about in today’s post. In this case, Primafond brings us closer to all these features.

More, sometimes, is not better.

⇒ TALKING ABOUT QUALITY

The adjectives that describe the characteristics of an efficient core shooter: versatile, practical, comfortable, fast, economical … important qualities which, unfortunately, are not easy to measure objectively.

Sometimes the bombastic branding of a trigger, together with aesthetics and clever advertising, pushes up the price, so it is well above the price of triggers from small manufacturers such as PRIMAFOND from Vicenza, Italy. As experience shows, the price difference is often not matched by superior features and performance.

AN EFFICIENT CORE SHOOTER MACHINE

⇒ A BALANCE MUST BE STRUCK

The premise is that investment in technological innovation and new equipment in the foundry is of vital importance to remain viable, efficient and to grow.

The union between the needs of foundries and the collaboration with machinery manufacturers, technically prepared and with constant doses of innovation, originates a positive evolution generating strong and efficient foundries.

Fundamental for the foundry is the choice of the manufacturer, since the latter must interpret the foundry’s needs, offering its experience, quality of equipment, good after-sales service and seriousness in the commercial relationship.

EFFICIENCY AND PRODUCTIVITY

In addition, in terms of productivity, for an efficient and profitable equipment, we must also consider other important aspects for the machining professionals:

- Simplicity of manoeuvres and commands.

- Ease of adjustment and removal of the taps.

- Easy assembly of the core box.

- Minimal and easy maintenance.

In particular, the choice of a shooter for large cores, e.g. to produce cores over 50 kg, must have been carefully considered, as these issues determine customer satisfaction.

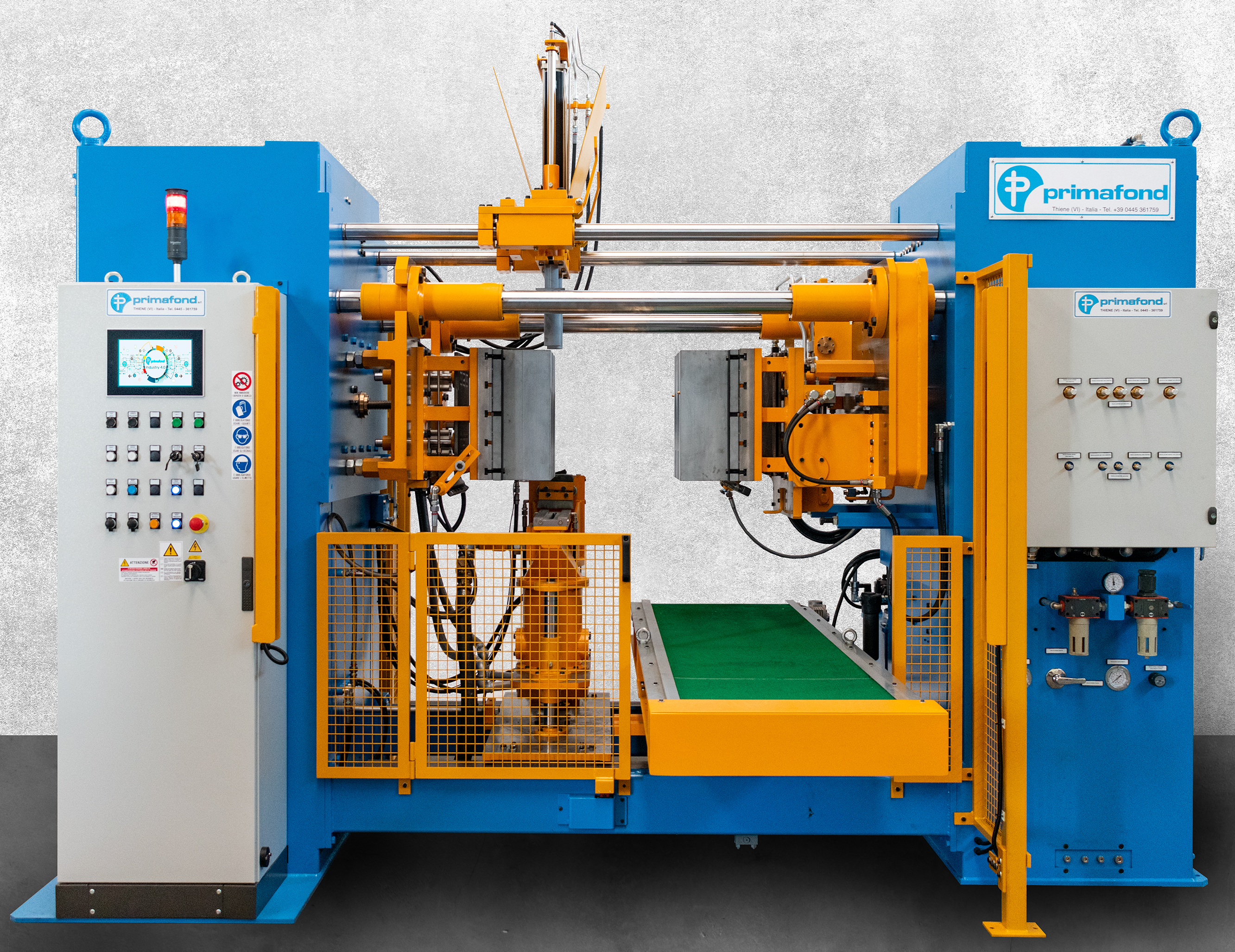

The PRIMAFOND SCB 40 – 60 – 80 to 100 series of core shooters for COLD BOX PRIMAFOND SCB 40 – 60 – 80 to 100, with capacities ranging from 40 to 100 litres, have so far been appreciated by the most demanding professionals in the production of medium and large sized cores. In common with machines of the same type from other manufacturers, PRIMAFOND’s “SCB” model shooters have the strength, power, hydraulic movements, automatic operation with PLC control, all of which are now basic elements thanks to the available technology. The company incorporates all the safety measures required for safe operation, simplicity of use and regulation, ease of assembly of the moulds and extraction of the cores, together with the ability to easily add any type of armature or hook to the comfortable working position.

PRIMAFOND designs and manufactures a complete range of Cold Box firing machines, with capacities from 5 to 100 litres, from the simplest and most universal firing machines for manual boxes, to automatic firing machines with constant outputs of 120 cycles/hour and machines for horizontal boxes with tools for extracting the core from the outside of the firing machine.

It completes its offer with the following equipment:

- Sand production and distribution plants for core making.

- Triggering machines for shell moulding.

- Automatic gas generators for the different processes.

- Amine neutralisers.

- Pneumatic senders.

- Tanks for core painting.

- Hydraulic and pneumatic ball breakers.

⇒ WHY DID WE CHOOSE PRIMAFOND?

The response of PRIMAFOND’s technicians to any need is always quick and direct, so PRIMAFOND will be the perfect partner in your foundry to improve your foundry, based on a solid experience acquired over the years, having attended to a multitude of needs and customizations of our customers, with a high degree of satisfaction. Our collaboration with EUSKATFUND aims to bring us closer to you in order to achieve the aforementioned objectives.

For the smelter, the choice of the manufacturer is crucial, as he must interpret the needs.

PROJECT AFTER PROJECT

EUSKATFUND is constantly evolving and developing. Thanks to projects like these, and the support we have received, we have managed to go a step further in the treatment and result of the materials we provide; never leaving aside one of our main values, that of being on the side of the environment whenever possible.

MORE POSTS YOU MAY BE INTERESTED IN

Properties & Applications of Ceramic Foundry Sand CERAMSAND

Ceramic sand has distinguished performance in foundry in compare with silica sand and other popularly used special sands. This article introduces the production process, the physical and chemical properties, and the application features of ceramic sand.

Sphere Ox, a feasible solution.

Veining, burns, penetrations and pinholes are common defects in castings and the daily struggle of foundries to control them. We tell you the solution.

THERMAL SAND RECLAMATION

Thermal reclamation has reached a point where, thanks to its innovations, it is profitable, economical and reliable.

INNOVATION R + D + I

EUSKATFUND collaborates with the technological research centres, laboratories and universities where it participates and develops projects with a high technological and environmental load.

We will tell you about some of them.