NEW PRODUCTION HALL FOR THE PRODUCTION OF SLEEVES AND RISERS

2,100 m2 of new space for the manufacture of high-performance sleeves and mini-risers. With this new hall, Euskatfund seeks to meet the manufacturing needs of this range of products and, in this way, to guarantee a greater supply to its customers.

We have expanded our facilities by dedicating this new section to the manufacture of feeders.

With the entry into operation of this new pavilion, Euskatfund completes its modern facilities of more than 7,000 m2.

This new pavilion is divided into 3 zones.

⇒ The first zone is for the storage of raw materials and tools.

⇒ In the central area, the production plant itself is located, comprising 5 Cold Box firing machines, ranging from 35 to 16 litres. We also have a Shell firing machine for the manufacture of pre-coated sand biscuits.

⇒ The last section of the hall is dedicated to the stock of finished products in order to guarantee a rapid response in the supply of our customers’ orders.

2.100 M2 más de pabellón

The compressor house and the amine neutraliser are located outside the central building. Increasingly stringent environmental regulations oblige us to pay the utmost attention to the working conditions in our core plant and thus guarantee the occupational health of our workers.

⇒ WHY IS THAT?

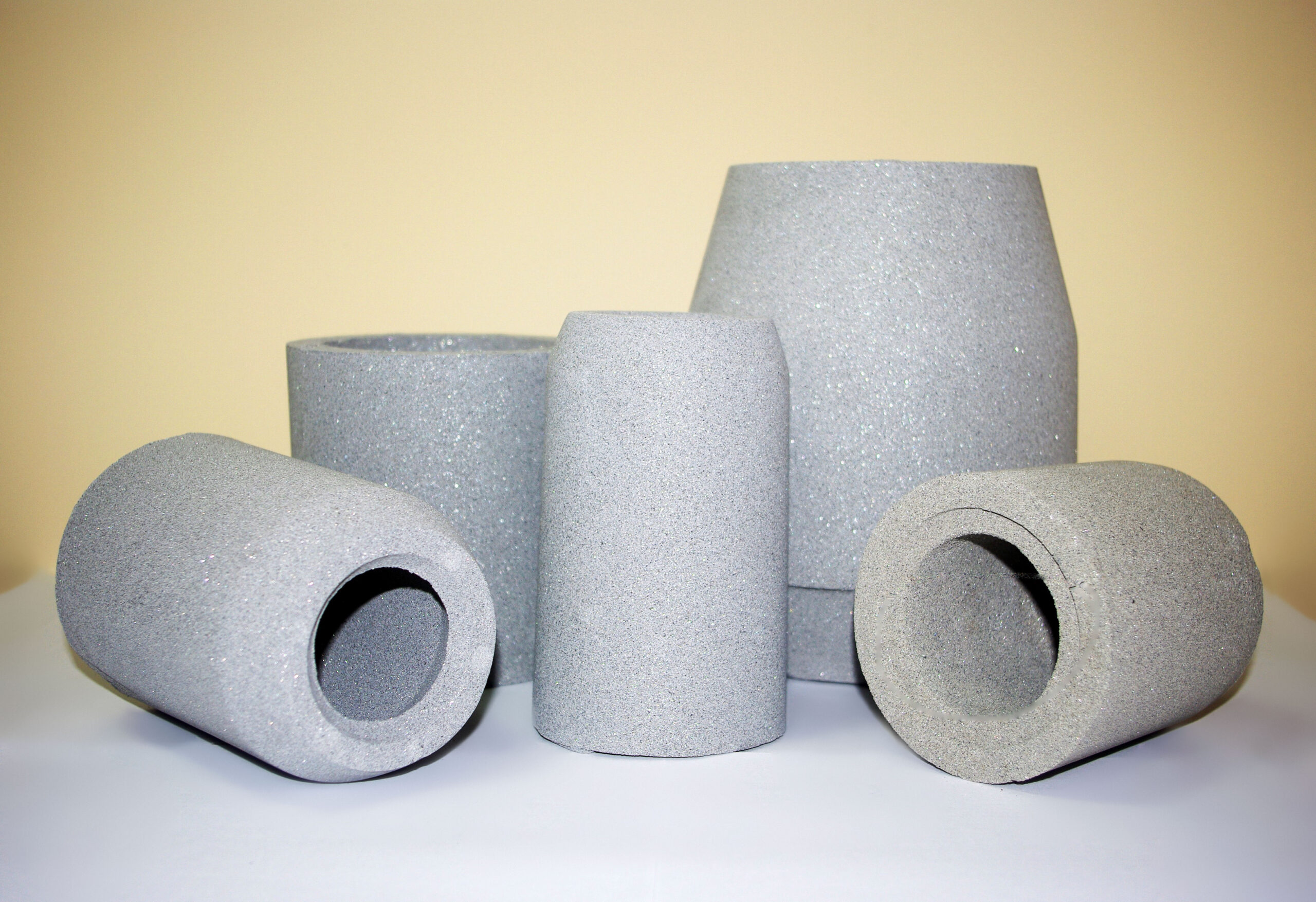

The growing demand for mini-caulks, from our customers, encouraged us to undertake the expansion with these new installations. The EURCAST EXO-U mini-muffs are low-density, high-performance sleeves. Their dimensions, with thicker walls than conventional sleeves, and their optimal exothermic-insulating formulation, give them a much higher exothermic modulus than traditional sleeves.

High performance for the casting of castings in iron, steel and all alloys of these metals, moulded in sand and other systems. MINI RISERS provide healthy parts, without porosity and without reaction of the metal with the sleeve.

⇒ WE INCREASE THE COMPANY AND QUALITY

Thanks to the technology applied to our EURCAST EXO HOSES AND MINI-MAZAROTS, products with constant characteristics are obtained:

✓ Good dimensional accuracy

✓ Stable quality

✓ High performance

✓ Reduced gauging costs

✓ Hygroscopic sleeves and mini-MAZAROTS, do not absorb humidity

✓ Exothermic-insulating

✓ Chemical homogeneity

✓ Fibre-free

✓ Minimal outgassing

WE CONTINUE…

A close and direct relationship with the technical departments of our customers allows us to design and manufacture any sleeve or mini-joint according to their design and power supply requirements.

We remain attentive to the needs and fluctuations of the market in order to undertake new investments.

We start every new project with the great support of our partners and customers and we can’t be left behind, we keep innovating.

PROJECT AFTER PROJECT

EUSKATFUND is constantly evolving and developing. Thanks to projects like these, and the support we have received, we have managed to go a step further in the treatment and result of the materials we provide; never leaving aside one of our main values, that of being on the side of the environment whenever possible.

MORE POSTS YOU MAY BE INTERESTED IN

Properties & Applications of Ceramic Foundry Sand CERAMSAND

Ceramic sand has distinguished performance in foundry in compare with silica sand and other popularly used special sands. This article introduces the production process, the physical and chemical properties, and the application features of ceramic sand.

Sphere Ox, a feasible solution.

Veining, burns, penetrations and pinholes are common defects in castings and the daily struggle of foundries to control them. We tell you the solution.

FUNCTIONAL CORE SHOOTER MACHINES

Adjectives that would describe the characteristics of an efficient core shooter are: versatile, practical, comfortable, fast, economical, …

THERMAL SAND RECLAMATION

Thermal reclamation has reached a point where, thanks to its innovations, it is profitable, economical and reliable.