FOUNDRY MACHINERY

We have pioneering brands in the foundry sector, machinery from specialised manufacturers for both core making, chemical moulding and green moulding. We maintain our ideals of being respectful with the environment, with occupational health as an obligation and without sacrificing the performance and profitability of each project.

CHEMICAL MOLDING | Omega

CORE-SHOP | Primafond

GREEN MOLDING | Belloi & Romagnoli

CHEMICAL MOLDING | Omega

CORE-SHOP | Primafond

Close

↑

Euskatfund represents OMEGA Foundry Machinery Ltd.

OMEGA’s design department is equipped with the latest computer and software technology to keep the company at the forefront of developing new and better equipment.

We have the human and technical resources necessary to supply, turnkey, any NO BAKE molding line.

Our teams comprise:

CHEMICAL MOLDING

CONTINUOUS SAND MIXERS

We have two series of high speed continuous mixers, the Spartan III and Spartan IV series.. Both series combine a robust construction with an innovative design providing optimal mixing quality for quality production of molds and cores.

Their main features:

✓ Complete range of pivoting and articulated mixers.

✓ Excellent access to the mixing tube for maintenance and cleaning.

✓ Efficient design for good mixing.

✓ Easy maintenance

✓ Robust construction

✓ Mixing capacity from 3 to 100 Tns. per hour.

Likewise, we also have:

⇒ Mobile mixers with a capacity of up to 100 TN/Hour, with the option of adjusting the height.

⇒ Mixers with double discharge tube for different sands and flow rates;

⇒ Portable pivoting mixers and;

⇒ 3-arm articulated mixers.

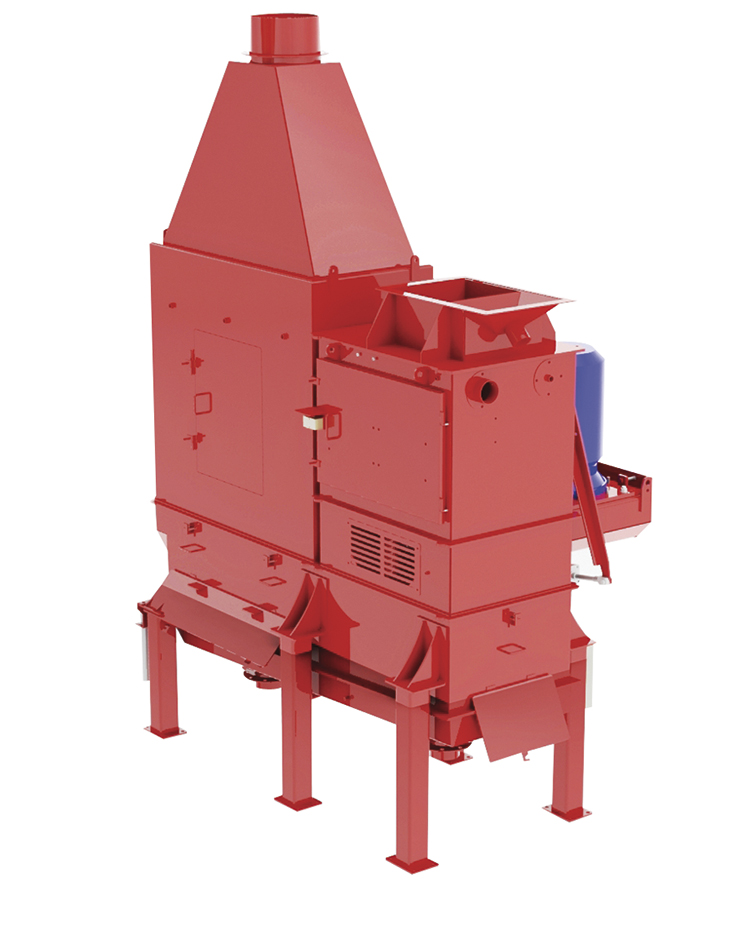

MECHANICAL SAND RECLAMATION

We have different Mechanical Sand Reclamation solutions to cover all your needs:

⇒ GAMMA VATOR sand recovery.

Range 1-3 Tns/Hour.

⇒ GAMMA LOW LEVEL sand recovery.

Range 6-15 Tns/Hour.

⇒ Sand recovery GAMMA HL HIGH LEVEL.

Range 6-30 Tns/Hour.

⇒ GAMMA MAJOR sand reclamation combination Shakeout and Reclamation.

Range 15-20 Tns/Hour.

⇒ GAMMA MAJOR PLUS sand reclamation. Combination of Shakeout and Reclamation.

Range 25-45 Tns/Hour.

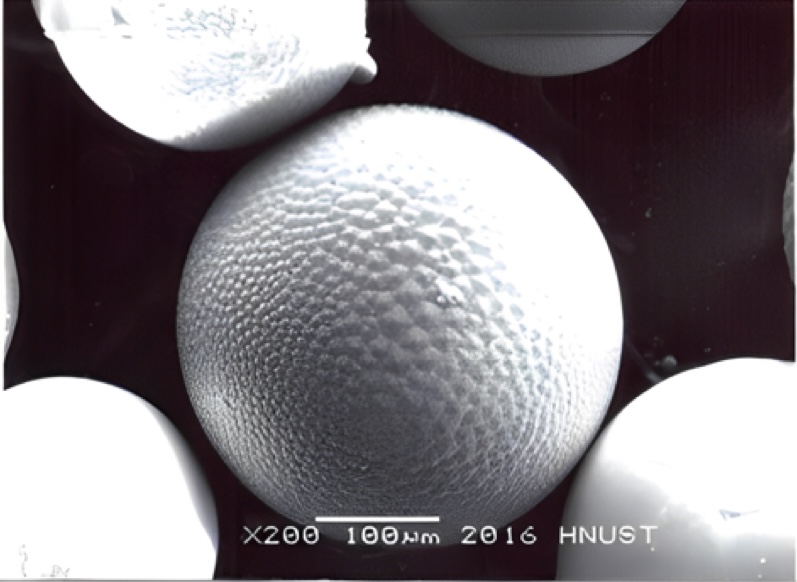

USR SECONDARY ATTRITION

USR to reduce the LOI through mechanical attrition without damaging the sand. We have 2 models:

⇒ USR units with one or two attrition drums.

⇒ USR units with recovery ranges of 5 or 10 Tns/Hour

Equipment characteristics to guarantee quality sand:

✓ Fluidized bed of minimum depth for good separation of fines.

✓ Stirring bars to separate fines from sand.

✓ Long-life ceramic rollers and drum.

✓ Low maintenance.

✓ Very low operating cost.

✓ Self lubrication.

✓ Adjustable grain cleaning control.

THERMAL RECLAMATION

We have a wide range of thermal reclamation machines ranging from 250 Kgs/hour to 12 Tns/hour, to thermally recover sand from all processes with binders. We highlight some of the main characteristics that have led us to be at the forefront of thermal reclamation of sand during the last 20 years.

✓ The design of the patented “Dead bed” insulation allows us to offer a 3 years warranty on the burners and the lining.

✓ High thermal efficiency and a heat recovery system. Gas consumption around 14 kg of LPG per ton of recovered sand.

✓ Extremely low maintenance. Equipment designed to work automatically, with full autonomy and with self-diagnosis.

✓ Very fast equipment startup times, around 30 minutes.

✓ It complies with all the standards of the most demanding regulations for CO2 emissions into the atmosphere.

CHROMITE SEPARATION

Our chromite sand separation systems ensure that the recovered chromite has a purity level > 98% key features:

✓ Ferrite drum magnet for removal of magnetic contaminants and chromite gangue

✓ High Intensity Rare Earth Magnet for Chromite Separation

✓ Third stage fluid bed density separator to ensure maximum purity of >98%

✓ Three plant sizes: 1, 5 and 10 tons per hour (TPH)

FOUNDRY CAROUSEL MACHINE

We offer different solutions for mold transportation and handling. The carousel system allows efficient use of space for molds up to 1,600 x 1,200 mm with 6 or 8 stations. Along with the molding carousel, automatic scrapers, turners, coating stations, drying ovens and manipulators can also be offered to operate with any mold or box size.

Due to its efficient use of space, the carousel is an alternative to the fast loop.

FAST LOOP

We propose countless solutions for the quick and efficient handling and handling of molds. We offer circuits that can work with molds up to 7,000 mm and other special measurements that our customers may require.

Along with the fast loop, we can offer elements such as: automatic scrapers, rollovers stripping station, flood coating, mould drying ovens and manipulators, to adapt to boxless moulds or metal boxes.

For this machinery, we rely on the reliability and performance of our partner Omega’s machines.

Speaking of CHEMICAL MOULDING MACHINERY,

You will be interested to have a look at our related products section, as we have, for example, no-bake resin systems, customised and ecological. Suitable for each type of metal.

Would you like us to advise you, place an order or get more information about machinery?

CONTACT US WITHOUT OBLIGATION

→

See less of chemical molding

Close

↑

Cerrar

↑

EUSKATFUND is the PRIMAFOND Representative for the Spanish market

PRIMAFOND’s design department is equipped with the latest computer and software technology to keep the company at the forefront of developing new and better equipment.

We have the necessary equipment to supply, turnkey, complete machinery.

CORE SHOP

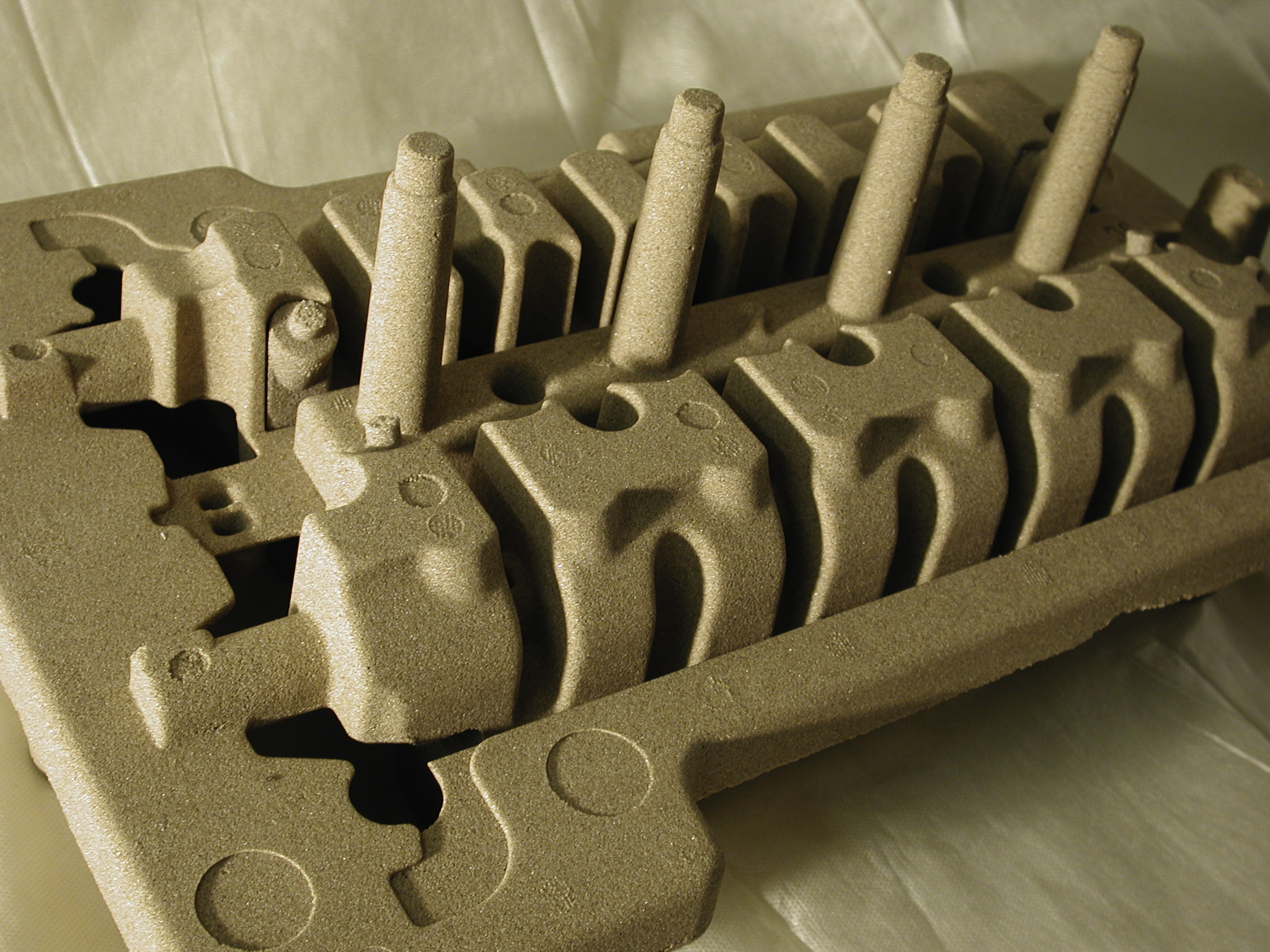

CORE SHOOTER MACHINES. COLD BOX AND INORGANIC PROCESS

Euskatfund offers core shooters, with gassing units, for any of the Cold Box processes.

We also offer our own range of Gassing units.

We can cover a wide range of needs that may be required of a core shooter:

⇒ Hydraulic

⇒ Pneumatic

✓ Horizontal or vertical box partition.

✓ Shooting capacities ranging from 2.5 to 150 Liters.

✓ Control panel with integrated PLC.

✓ Gassing units for Amine, Methylformate, Isoset or CO2 (optional).

✓ Ejector plate for horizontal boxes (optional).

✓ We supply our entire range of Core Shootters adapted to work with the inorganic system.

CORE SHOOTER MACHINES. SHELL MOULDING PROCESS

Euskatfund offers Shell Molding core shooters from our represented PRIMAFOND.

We can cover a wide range of needs that may be required of a male shooter:

⇒ Hydraulic

⇒ Pneumatic

✓ Shooting capacities ranging from 5 to 100 Liters.

✓ Control panel with integrated PLC

✓ Heating of the box by gas or with electric resistances (optional).

✓ Third part (optional).

✓ Independent box temperature control on the 2 panels.

✓ Core shooter with rotating mold with shooting from above, below or during rotation.

✓ Automatic core shooter, with firing from below, for automatic cycles and with a folding mold to deposit the cores on the belt.

✓ Semi-automatic core shooter with shooting from the side, horizontal partition, to be able to place rods to reinforce the cores.

SAND PREPARATION AND DISTRIBUTION SYSTEMS

PRIMAFOND offers complete sand preparation systems for the manufacture of foundry cores, meeting all the requirements of current technology. Taking into account all aspects of current foundry core sand preparation methods, creating ideal preconditions for producing high quality foundry cores.

The facilities for the preparation and distribution of sand are made up of two main groups:

- Sand and resin mixture

- Distribution of the pre-mixed sand to the different core shooters

Some important features of our equipment are:

✓ Easy but effective preparation. High efficiency process.

✓ Optimal integration into core production systems thanks to easy-to-use IT technology.

✓ High level of operational security.

AMINE NEUTRALIZERS | SCRUBBERS

The increasingly demanding environmental regulations force us to maintain maximum attention to the working conditions of our machinery.

We put at your disposal our wide range of amine neutralizers or Scrubber.

Amine Neutralizers or Scrubber are equipment that captures and neutralizes the amine that is in a gaseous state.Using a washing system with a solution of water and sulfuric acid, or orthophosphoric acid, a reaction is achieved so that the amine is precipitated and transformed into a neutral salt, amine sulfate.

HYDRAULIC WEDGE BREAKERS

PRIMAFOND manufactures a wide range of hydraulic wedge riser breakers, with the following specifications:

⇒ Hydraulic control unit with single pump.

⇒ Operating power of 320 bar.

⇒ Wedge advance speed of about 100mm per second.

⇒ The SMAT 50G – 63 – 80 – 100 models have a rotating head, which facilitates the entry position of the wedge.

⇒ The SMAT 50 MINI model has a fixed head. It is easy to use and fast. It is mainly used when there is little space between the piece and the sprue.

ADVANTAGES of the equipment:

✓ Cost reduction thanks to the speed of the operation.

✓ Minimum investment.

✓ Better work environment and operator safety than other dismantling systems.

✓ Simple installation.

✓ Easy to use.

Primafond’s design department is equipped with the latest computer technology and cutting-edge software. At Euskatund we count on Primafond because they collaborate with our ideals of maintaining safety and efficiency, going one step further and guaranteeing results in the most demanding projects.

Talking about CORE SHOP,

You will be interested to have a look at our related products section, as we have cold box resins, pre-coated sands, silica sands, refractory coatings and additives, …

Would you like us to advise you, place an order or get more information about machinery?

CONTACT US WITHOUT OBLIGATION

→

See less of core shop

View less of core shop

MOLDING IN GREEN | Belloi & Romagnoli

Close

↑

Cerrar

↑

Euskatfund represents BELLOI & ROMAGNOLI Srl.

BELLOI & ROMAGNOLI’s design department is equipped with the latest computer technology and has expert technicians capable of keeping the company at the forefront of developing new and better equipment.

We have the necessary equipment to supply, keys on hand, any green molding line.

GREEN MOLDING

MOLDING MACHINES WITH MULTIPISTON HEAD

To form the mold, the sand compaction is first triggered by air impact, and the mold is finished by hydraulic compression. This process allows for even distribution of sand during air impact. Hydraulic compression provides uniform mold hardness for all surfaces and vertical parts of the model and also around the edges of the case.

Settings for air impact and hydraulic compression are adjustable through the operator interface. This machine can be used with existing models. There are no problems with the use of models and plates made of wood, resin, aluminum, etc.

The noise level emitted by the machine is less than 80 dB (A).

INTENSIVE GRREN SAND MIXERS

The mixer is, rightly considered, the heart of the sand making plant, which is, obviously, the most important machine to achieve the ideal parameters of the molding sand.

Over the years, we have seen the most diverse types of mixers on the market, with intensive mixers being the ones that set the standard today. Its main features are:

✓ Land production of uniform quality

✓ High productivity

✓ Reliability

✓ Low Maintenance

Our range of mixers covers needs from 10 to 150 Tns/hour.

GREEN SAND COOLERS

Effective cooling and humidification of the return sand is important to ensure optimal sand quality.

The cooling drum has been designed to provide modern foundries with the possibility of simultaneously cooling the earth and the castings and to facilitate the cleaning of the latter by also controlling the aspiration of sand fines.

The castings are transported from a vibrating channel to the drum where they are demasked. The cooling process is based on the evaporation of residual moisture from the sand and the return of water evaporation, appropriately dosed by a conditioning device. It is made up of two phases:

1. Introduction of water into the loading area of the drum, depending on the temperature of the sand.

2. Introduction of water, if necessary, at the outlet of the drum.

AUTOMATIC GREEN SAND CONTROL GSC

Sand quality is a fundamental aspect of mold quality and is therefore also essential for high productivity in high-quality castings.

Designed for use with high-capacity mixing mills, the “GSC” system regulates and monitors the process, in the sand mixing mill, and ensures that the characteristics of the sand prepared for molding remain within a constant range. The regulation is carried out automatically and through an analysis of the sand during the mixing process. The analyzes are based on precise measurements of the temperature, humidity, compactability and green strength of the sand.

Equipment features:

✓ Online control and supervision with a Siemens S7 PLC connected to a Siemens TP270 touch-panel

✓ Compatible with all types of large capacity mixer grinders

The comprehensive manufacturer of green moulding machinery on which we rely is the great brand Belloi & Romagnoli.

It manufactures horizontal moulding machines with multi-piston heads, complete sand plants, automatic sand plant controls, cooling drums and all the peripherals necessary for a sand plant and moulding line.

Would you like us to advise you, place an order or get more information about machinery?

CONTACT US WITHOUT OBLIGATION

→

See less of green molding

See less of green molding

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

Find out about all our projects and news in our blog

I WANT INFORMATION ABOUT ORDERING

Whether you need to place a new order, or if you have any doubts about them, processes, etc. Do not hesitate to write to us, without obligation.

I WANT INFORMATION ABOUT ORDERING

Whether you need to place a new order, or if you have any doubts about them, processes, etc. Do not hesitate to write to us, without obligation.