PRODUCTS FOR FOUNDRY

Euskatfund manufactures and sells a wide range of products to meet your needs. Always respectful of the environment and workplace health, without sacrificing performance and profitability.

NO-BAKE BINDER SYSTEMS

PRE-COATED SANDS

SILICA SANDS

Close

↑

Self-setting synthetic resins, from the reaction between furfuryl alcohol and/or phenol and urea-formaldehyde and hardening with acid or ester catalysts, are commonly used in foundries for the manufacture of molds and cores.

EUSKATFUND offers a wide range of personalized and ecological NO-BAKE systems, suitable for each type of metal, according to the required setting times, the different types of sand (new or recovered), with high mechanical resistance, which confer excellent surface fineness. to the pieces.

NO-BAKE BINDER SYSTEMS

FURANIC RESINS

EUSKATFUND designs and manufactures a wide range of furan resins with excellent characteristics:

✓ Molds with high mechanical resistance and good thermal shock behavior.

✓ Low addition of binders.

✓ Low viscosity.

✓ Low emissions during the molding and melting phase.

✓ Very reactive systems to obtain the best performance in the most demanding Fast Loops.

✓ Slower systems to be able to work large molds that are difficult to attack, in extreme temperature conditions, both ambient and hot and highly acidic sands.

Special mention should be made of the systems free of Formaldehyde, Phenol, Nitrogen and water, which guarantee a good surface quality of the parts, without metal/mold reaction, especially in nodular iron and steel parts.

ALKALINE PHENOLIC RESINS

EUSKATFUND designs and manufactures a range of alkaline phenolic resins with excellent characteristics:

✓ The URSET range of resins do not contain Nitrogen or Sulfur.

✓ Particularly suitable for steel casting.

✓ As it is not an exothermic system, it minimizes the problem of hot cracks in steel castings.

✓ This system facilitates excellent demolding.

✓ Emissions, both in the molding phase and in the casting phase, are very low.

✓ The process does not generate harmful or irritating odors, thus improving the workplace.

We have soda-based resins, suitable for working with mechanically recovered sand, achieving very good mechanical characteristics.

Potash-based resins are recommended for foundries that always work with new sand.

PHENOLIC URETHANE RESINS

EUSKATFUND offers a range of phenolic urethane resins with excellent characteristics:

✓ The Phenolic Urethane system allows high productivity.

✓ High bench life in relation to the setting curve.

✓ Low gas evolution and very acceptable odor levels.

✓ Good fluidity of the sand, due to the low viscosity of the resins, which allows obtaining good surface finishes of the cast parts.

✓ Free of Sulfur and Phosphorus.

Talking about NO-BAKE BINDER SYSTEMS,

You will be interested to take a look at our related machinery section, as we have, for example, this articulated mixer, perfect for moulding large parts.

Manufacturer: OMEGA

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of no-bake binder systems

Close

↑

Cerrar

↑

Pre-coated sand is a sand, normally siliceous, coated with a flake novolac or a liquid phenolic resin, which is used for the manufacture of cores and molds through the process known as Shell molding or Croning.

CHARACTERISTICS

✓ The cores made through this process have high mechanical resistance when cold.

✓ Excellent system fluidity.

✓ Low gas development during the fusion process.

✓ The pieces obtained through this work process stand out for their excellent surface appearance and high dimensional precision.

✓ The shells and cores produced by the Croning process are hygroscopic.

✓ The design of a pre-coated sand is subject to the type of piece that you want to cast. Parameters such as the AFA of the sand, the amount of organics and the presence of additives such as magnetites, chromite, refractory minerals, etc. will depend on the shape of the core, characteristics of the piece and the alloy to be cast.

EUSKATFUND covers a wide range of aggregates such as Cerabeads, Chromite, Kerphalites, Synthetic Sands, etc., depending on the needs of the pieces to be cast.

PRE-COATED SANDS

Talking about PRE-COATED SANDS,

You might be interested to take a look at our machinery section. We have systems that complement each other perfectly. Like this Shell Moulding machine, remarkable for its avant-garde equipment.

Manufacturer: PRIMAFOND

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of pre-coated sands

See less of pre-coated sands

SILICA SANDS

CERAMIC GATING SYSTEMS

Close

↑

Close

↑

High quality silica sand, suitable for use in foundries, in molds and cores with high demands

✓ Available in different granulometries.

✓ Sands with rounded and sub-angular grains.

✓ High SiO2 content > 99%

✓ Due to its high silica content, the refractoriness of the sand is especially high, thus avoiding veining, calcination and penetration problems.

✓ Low content of Al2O3 alumina and other oxides: Fe2O3, CaO, TiO2 and K2O.

✓ Good granulometric distribution that gives the mold, and/or the attacked core, a surface with low roughness.

✓ Low percentage of fines in the sand giving it good permeability.

SILICA SANDS

Talkign about SILICA SANDS,

To guarantee the quality of our deliveries, we work with our partner SÍLICES GILARRANZ, which has facilities for washing, classifying and drying the sands.

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of Silica Sands

Ver menos de Arenas Sílice

CERAMIC GATING SYSTEMS

CERAMIC FOAM FILTERS

COLD BOX BINDER SYSTEM

Close

↑

Cerrar

↑

GATING SYSTEMS, NOZZLES AND STOPPERS

Euskatfund distributes a wide range of shaped ceramic and graphite products.

✓ We cover all your needs to design your gating systems and ladle closing systems.

✓ Rigorously selected raw materials achieve a product with high resistance to liquid penetration and stable to thermal shock, with alumina contents that cover a range of 37 to 80% depending on needs.

✓ Special geometries can be attended, according to customer needs.

CERAMIC GATING SYSTEMS

Talking about CERAMIC GATING SYSTEMS,

For the production of ceramic ducts, bushings, stoppers and graphite plugs, we rely on our partner SEEIF. They always guarantee the quality of their materials.

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of ceramic gating systems

See less of ceramic gating systems

CERAMIC FOAM FILTERS

COLD BOX BINDER SYSTEM

Close

↑

Cerrar

↑

EURCAST-FOAM CERAMIC FOAM FILTERS

EURCAST-FOAM ceramic foam filters are used to filter all types of smelting.

EURCAST-FOAM filters make it possible to reduce flow turbulence during mold filling and thus avoid unwanted oxidation, inclusions and defects of castings. This is possible because the turbulent flow of molten metal transforms into laminar flow after filtering. Ensuring a constant flow is another important mission of the filters.

CERAMIC FOAM FILTERS

SiC FILTERS

EURCAST-FOAM SiC ceramic foam filters are used in the casting of Lamellar Iron and Spheroidal Iron parts up to a temperature of 1,500ºC.

✓ Foam filters help achieve lower production cost and improve the quality of the final casting.

✓ Significant savings in molten metal (elimination of up to 50% of the weight of the casting system).

✓ Lower rejection rate and lower cost of finishing operations (work tools).

✓ Improved properties of the cast part (greater homogeneity, precision of shape, better surface finish).

✓ Homogeneous porous structure with a minimum of obstructions.

✓ Fast filling with minimal heat loss.

✓ High pouring capacity and flow rate.

ZR FILTERS

EURCAST-FOAM ZR (Zr02) ceramic foam filters are used for filtering steel alloys up to a temperature of 1,700ºC.

✓ Foam filters help achieve lower production cost and improve the quality of the final casting.

✓ Significant savings in molten metal. Elimination of up to 50% of the weight of the casting system and simplification of the design and filling system.

✓ Lower rejection rate and lower cost of finishing operations (work tools and time).

✓ Improved mechanical properties of the cast part (greater homogeneity, shape precision, better surface finish).

✓ Fast filling with minimal heat loss.

✓ High pouring capacity and flow rate.

✓ Filters can be placed in different positions within the casting system.

HTX FILTERS

Carbon-based ceramic foam filters. EURCAST-FOAM HTX ceramic foam filters are used for filtering iron with high Cr content, and low alloy steels up to a temperature of 1,700ºC.

They are made from carefully selected ceramic raw materials, which give the filters special properties:

✓ Very light.

✓ High thermal conductivity, allowing rapid priming with minimal heat loss.

✓ Slag resistant.

✓ High levels of hot resistance.

FILTERS AL

Ceramic foam filters whose main raw material is AL2O3.

AL ceramic foam filters, for application in foundries, are designed for the filtration of aluminum and aluminum alloys up to a temperature of 1,200 °C, especially for gravity casting in sand, ceramic or metal shell moulds.

✓ Foam filters help achieve lower production cost and improve the quality of the final casting.

✓ Very light.

✓ Filters can be placed in different positions within the casting system.

✓ Homogeneous porous structure with a minimum of obstructions.

✓ High pouring capacity and flow rate.

LD FILTERS

Ceramic foam filters whose main raw material is Alumina.

LD ceramic foam filters, for application in foundries, are designed for the filtration of aluminum and aluminum alloys up to a temperature of 850 °C, especially for gravity casting in sand, ceramic or metal shell moulds.

✓ Very light. Low density and therefore good buoyancy. They are easily skimmed off when skimming.

✓ Filters can be placed in different positions within the casting system.

✓ LD filters help produce higher quality parts at lower production costs.

✓ Homogeneous porous structure with a minimum of obstructions, guaranteeing its filtration capacity and pouring speed.

We look for and find efficiency and quality.

You may be interested in this video of one of our trusted manufacturers, in which he explains the whole process and advantages of their ceramic filters.

Manufacturer: FCRI

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of ceramic foam filters

See less of ceramic foam filters

Close

↑

Cold Box processes are the prevailing systems in the manufacture of cores and shot molds today. Good productivity and efficiency guarantee good performance. A wide range of systems covers the specific needs of foundries.

COLD BOX BINDER SYSTEM

Methylformiate hardening

CHARACTERISTICS

✓ Working process especially suitable for the casting of steel, nodular iron and aluminum.

✓ An advantage of this process is that the binder does not contain Nitrogen or Sulfur, and the Carbon level is very low.

✓ The good thermostability of the system prevents cracks in the cores so, in many cases, it is not necessary to apply refractory coating to protect them.

Amine hardening

CHARACTERISTICS

✓ Work process that allows very high productivity.

✓ Obtaining high quality castings

✓ Excellent cold mechanical resistance that allows comfortable handling of the cores/specks.

✓ Availability of different COLD BOX systems to solve specific part defects.

Talking about COLD BOX BINDER SYSTEM,

You will be interested to take a look at our machinery section. We have systems that complement each other perfectly. Like this core shooter, remarkable for its state-of-the-art equipment.

Manufacturer: PRIMAFOND

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of cold box binder system

See less of cold box binder system

RISER AND SLEEVES

REFRACTORY COATINGS

STEEL SHOTS

RISERS AND SLEEVES

REFRACTORY COATINGS

Close

↑

Cerrar

↑

RISERS AND SLEEVES

EUSKATFUND manufactures a wide range of sleeves and risers to cover all the needs of the foundry. Fiber-free sleeves. The range of sleeves WITHOUT fluorine, avoids “fish-eye” defects in the pieces fed in green molding and avoids contamination of the sand, of this component, adjusting to the requirements of landfills.

RISER AND SLEEVES

SLEEVES

EURCAST sleeves are used in casting pieces of sheet iron, spheroidal iron, steels, aluminum and copper alloys.

CHARACTERISTICS

✓ Insulating and Exothermic Sleeves.

✓ Conical, cylindrical, oval, precision insertable sleeves, casting sleeves with built-in filter.

✓ EUSKATFUND sleeves prevent defects resulting from contraction.

✓ Improves smelting performance.

✓ Significant improvement in the amount of metal poured, improving performance.

✓ Significant improvement in deburring and cleaning operations.

✓ BREAKER CORE. Composed of silica sand and chromite sand, resistant and without reaction. Flat, conical and oval breaker core.

MINI RISERS

The EURCAST-EXO-U mini risers are applied in casting large pieces in steel and ductile iron alloys.

CHARACTERISTICS

✓ The properties of the raw materials used in the composition and their exothermicity, together with the design of each type, give us high-performance and extremely light mini risers.

✓ The high performance achieved, especially in Steel and Ductile Iron, reduces the cost of parts by improving performance in relation to traditional sleeves.

✓ Another characteristic that the use of mini risers gives us is productivity. The smaller volume that we achieve with the mini risers allows us to have a greater contribution of broth to melt.

✓ BREAKER CORE. Composition of silica sand, chromite sand, resistant and reaction-free for mini risers, with choked neck and metal breaker core for high pressure molding.

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of riser and sleeves

See less of risers and sleeves

Close

↑

Cerrar

↑

Refractory Coatings, better known as Coatings in foundries, are applied to the surfaces of molds and cores. The function of the Refractory Coating is to protect the sand or aggregate, used in the molding phase, from the thermal stress suffered by these molds and cores in the casting phase and prior to solidification.

EUSKATFUND has a wide range of Coatings, water-based and alcohol-based, suitable for steel, iron and non-ferrous foundries.

We also have Coatings for special processes such as centrifuged cylinders or Coatings for polystyrene models.

CHARACTERISTICS

✓ Refractory Coatings specifically designed according to the application: Pouring, immersion, spray or brush.

✓ We use high purity refractory materials to offer greater protection to the molds and cores in the most extreme conditions of temperature and high metallostatic pressures.

✓ Obtaining a high surface quality of the cast parts.

✓ Our Coatings, and a correct application, avoid surface defects of the cast parts such as veining, calcinations and penetrations, pinholes, etc.

REFRACTORY COATINGS

Talking abour REFRACTORY COATINGS,

Did you know that we are a supplier of pioneering brands in the sector? For example, for some auxiliary materials and for refractory coatings we have our partner Mazzon.

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of refractory coatings

See less of refractory coatings

STEEL SHOTS

REFRACTORY – FURNACES

Close

↑

Cerrar

↑

There are two technologies for projecting shot: turbine shot blasting or air blasting.

Shot blasting is an abrasive projection method that is used to:

✓ Cleaning the surfaces of cast parts.

✓ Preparation of surfaces for painting or enamelling.

✓ Cutting blocks of stone or marble.

✓ Improve the fatigue resistance of components subject to high alternating stresses (Shot Peening).

EUSKATFUND sells high and low carbon shot.

STEEL SHOTS

LOW CARBON ROUND STEEL SHOT

High quality steel shot, suitable for use in any shot blasting operation.

✓ Bainitic microstructure, free of cracks, which is achieved in the tempering process due to the use of selected scrap with low Carbon, Sulfur and Phosphorus content.

✓ Low Carbon shot blasts harden, up to 46-49 HRC, in the first shot blasting cycles, due to their higher manganese content.

✓ The low Carbon and high Manganese content grits are resistant to impacts, being more tenacious and resistant to wear, improving their performance.

✓ Wear occurs due to the detachment of layers, like in an onion, in 80% of its useful life.

✓ Less amount of broken shot will cause less wear on the blades, turbine and shot blasting machine in general.

✓ Steel Shot grit recommended for working in foundries, forges, rolling and calibrating mills, machinery construction, automotive, aeronautics and structural steel industries.

HIGH CARBON ROUND STEEL SHOT

High quality steel shot, suitable for use in any shot blasting operation.

✓ High carbon steel shot from the melting of properly selected steel scrap.

✓ Through specific heat treatments and precise sieving, excellent quality steel shot is obtained.

✓ Suitable for the shot blasting and blasting process.

✓ Martensite microstructure according to SAE J827 with spherical shapes.

✓ Hardness (in operation): 45-52 HRC

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of steel shots

See less of steel shots

REFRACTORY – FURNACES

FERROALLOYS AND RECARBURANTS

AUXILIARIES PRODUCTS

Close

↑

Cerrar

↑

EUSKATFUND distributes a wide range of products from CAPITAL Refractories, an English company, leader in the sector, with factories in the UK, USA, China and India.

We cover many thermal process applications.

Our areas of specialty include:

⇒ CORELESS INDUCTION FURNACES

· Refractories for Induction Furnaces

· Repair material

· Coil Screed for induction furnace

· Rampable mass for spout and crown

· Dry refractory for Induction Furnace crown

· Dry refractory for crucible blocking

· Porous gas diffuser plugs

⇒ LADLES LININGS

· Refractory mortar

· Refractory wet cement for joining stopper and repairs.

· Mica paper rolls

⇒ CRUCIBLES FOR MICROFUSION

⇒ SPOUTS AND DISTRIBUTION BOXES FOR THE CASTING OF SUPERALLOYS

⇒ FLOW CONTROL NOZZLES

· Unibore System

REFRACTORY – FURNACES

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of refractory – furnaces

See less of refractory – furnaces

FERROALLOY

AUXILIARIES PRODUCTS

Close

↑

Cerrar

↑

Ferroalloys are an iron alloy that contains metallic elements such as Silicon, Manganese, Chromium, Nickel, Molybdenum, among others.

These mixtures are used in foundries to improve the properties of iron and steels, such as resistance, hardness, corrosion or electrical conductivity, according to specific needs.

FERROALLOYS

FERRO SILICON

✓ It contains around 25% iron and 75% Silicon in its structure.

✓ Increases mechanical resistance.

✓ Minimizes iron oxidation, protecting it against wear and corrosion.

✓ Low electrical conductivity

✓ Used as a base for the manufacture of inoculants and nodulizers.

FERRO MANGANESE

✓ It contains around 25% iron and 75% manganese.

✓ Increases resistance and hardness.

✓ Increases toughness and reduces the chances of fractures.

✓ Deoxidizing and desulfurizing agent.

✓ Increases corrosion resistance.

✓ Improves resistance to high temperatures.

FERRO CHROME

✓ Increases corrosion resistance, preventing deterioration due to oxidation.

✓ Increased mechanical resistance and hardness.

✓ It is ideal in applications where high resistance to high temperatures is required.

✓ Ferro Chromium is an important source of chromium in the manufacture of Stainless steels.

SILICIUM CARBIDE

✓ Recarburant and deoxidizer for iron and steel foundries.

✓ Alternative, in the charge, of graphite and Ferro Silicon.

✓ It decomposes in an exothermic reaction that raises the temperature of the broth, saving energy.

✓ Extends the life of the furnace refractory.

✓ The slag generated is more consistent allowing for easier removal from the furnace.

RECARBURANTS

⇒ Graphite low Sulfur electrodes. Suitable for recarburizing Spheroidal Iron

– Granulometry 1-5 mm.

– Carbon > 98%

– Sulfur < 0.05%

⇒ Calcined Petroleum Coke Recarburant. Suitable for recarburizing Grey Iron.

– Granulometry 0.2-4 mm.

– Carbon > 98%

– Sulfur < 1.15%

¿Quieres que te asesoremos, hacer un pedido, …?

CONTACTA SIN COMPROMISO

→

See less of ferroaloys

See less of ferroalloys

Close

↑

Cerrar

↑

Euskatfund offers a wide range of additives to improve the characteristics of its molds and sand cores, as well as solvents, glues for molds and cores, mold release agents and special sands to be used both in the molding area and in the core making.

AUXILIARIES PRODUCTS

CHROMITE SAND

Special Sand, used for Mouldmaking and Coremakin, with a high percentage of Chromium, which gives special characteristics to the molds and cores, avoiding various metal-mold problems.

CHARACTERÍSTICS

✓ Excellent properties at high temperatures. Heat resistant.

✓ High resistance to liquid metal penetration.

✓ High thermal conductivity.

✓ Low thermal expansion.

✓ Compatible with all molding and machining binding systems.

✓ Constant granulometry.

✓ Recurrently used in the molding of large pieces of iron and steel.

✓ Compared to silica sand, it is less reactive with manganese oxide, thus reducing the problems of calcination and metal-mold reactions.

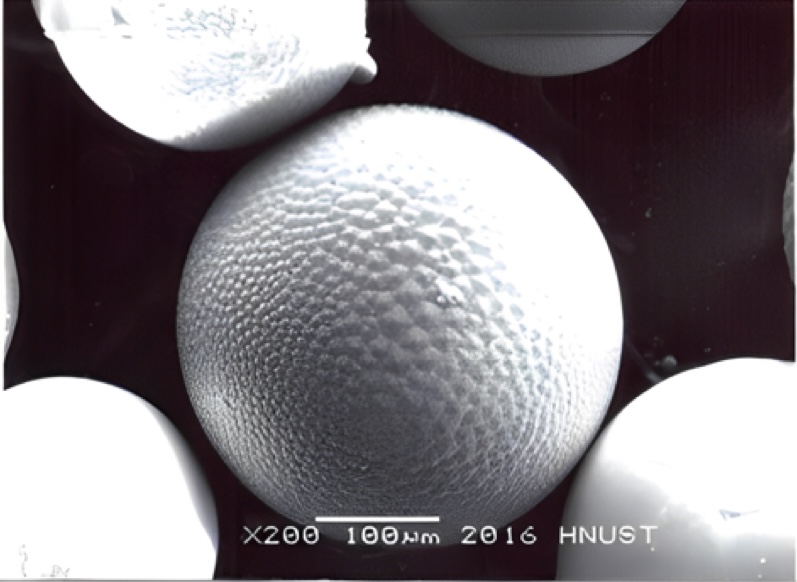

CERAMIC SAND CERAMSAND

CERAMSAND ceramic sand is a synthetic sand, crystalline silica sand-free, made from high-quality bauxite. It is produced using a unique manufacturing process that creates a ceramic bead with a uniformly spherical grain shape and a smooth surface.

CERAMSAND ceramic sand is an effective replacement for silica sand, chromite sand and olivine sand in various molding and core systems, as well as for 3D printing.

CHARACTERISTICS

✓ Free of crystalline silica sand.

✓ High termal stability.

✓ Low termal expansion.

✓ High refractoriness.

✓ Excellent flowability.

✓ Low binder consumption.

✓ Easy shakeout.

✓ Good Surface finish of casting.

✓ Compatible with all molding binder and core systems.

✓ Reusable and recyclable.

SPHERE OX Synthetic Iron Oxide

Additive used for mouldmaking and coremaking sands, which can be used in various percentages depending on its application and type of part.

CHARACTERISTICS

✓ It exponentially improves the results obtained with natural magnetites.

✓ Great cooling capacity

✓ High oxide absorption capacity during casting, reducing gas defects (pinhol).

✓ Improves the permeability and mechanical resistance of the mold or core.

✓ Reduction in the percentage of binder.

✓ Improves the fluidity of the mixture.

✓ Reduces shiny carbon defects.

✓ Reduction of deburring times

ALCOHOLS

Solvents, used in Foundries, to dilute refractory coatings and, in this way, adjust them to the desired density and viscosity.

⇒ TECHNO PLUS. Deodorized Isopropyl Alcohol.

⇒ TECHNO MIX. Isopropyl/Ethyl mixture.

GLUES

Glues for cold curing applications for joining molds and cores.

CHARACTERISTICS

⇒ EUR-COLA NL.

–Inorganic cold glue.

– Used to join specks or molds, agglomerated with resins, which prevents leaks during filling of the mold.

-Also used to seal the covers so that the liquid does not close the air outlets of the core, causing blows.

⇒ EUR-COLA HF.

– Sealing glue, like NL, but denser and more reactive.

⇒ SPEED GLUE PR.1.

– Speed glue, with solvents, for cold cores.

–Used for gluing resin cores or for recovering broken cores.

MOULD SEALS

Plastic cord used to close the two parts of the mold.

CHARACTERISTICS

⇒ CORDON-PLAST

✓ Available in ∅ 4.5; 6; 8; 10; 12; 15 and 20 mm.

✓ Flexible and with high plasticity.

✓ Prevents broth leaks when filling the mold.

✓ Increases the life of molding boxes.

RELEASE AGENTS

The release agents facilitate easy demolding of the molds and cores, protecting, in turn, the models and core boxes.

EUSKATFUND distributes the range of ACHEM release agents, manufactured by Angewandte Chemie GmbH, covering all the needs of the foundry:

⇒ Release agents for green sand casting.

⇒ Release agents for NO BAKE systems.

⇒ Release agents for COLD BOX systems.

⇒ Mold release agents for HOT BOX and SHELL MOLDING systems.

⇒ NON-FERROUS Die Casting Mold Release Agents.

DESLAGGING AGENT

Slag binding agent that is especially indicated for application on slags that have a low viscosity. When these slags are treated with our deslagging agents, they are transformed into a plastic compound that can be easily removed.

Available in:

– Granolumetry 0.4-1.2 mm.

– Granulometry 1.2-2.8 mm.

COVERING POWDERS

Powders with high insulating capacity used as a covering layer on ladles and risers. Prevents molten metal from coming into contact with air, which helps prevent rust.

⇒ PIROMAC 100/C. Insulating covering powders for furnaces and ladles.

⇒ FUNKAT E. Exothermic covering powders with high insulating properties for feeders, iron and steel castings.

SAND RECOVERY ADDITIVE

Water suspension used in recovered sands, resulting from the alkaline phenolic process, with organic hardeners.

✓ The additive is added in the mechanical treatment of recovered sand, before thermal recovery.

✓ Reduces excess potassium in sand

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

See less of auxiliaries products

See less of auxiliaries products

Would you like us to advise you, place an order, …?

CONTACT US WITHOUT OBLIGATION

→

Find out about all our projects and news in our blog.

I WANT INFORMATION ABOUT ORDERING

Whether you need to place a new order, or if you have any doubts about them, processes, etc. Do not hesitate to write to us, without obligation.

I WANT INFORMATION ABOUT ORDERING

Whether you need to place a new order, or if you have any doubts about them, processes, etc. Do not hesitate to write to us, without obligation.